|

|

|

| |

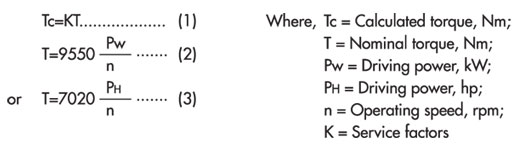

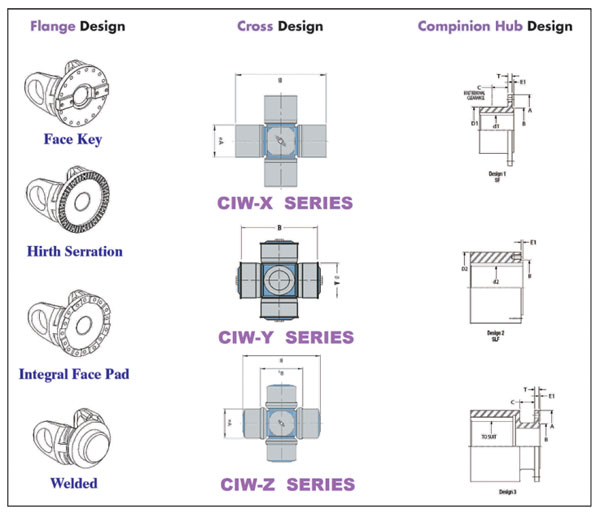

According to standard, use the

following methods to select CIW-X,

CIW-Y and CIW-Z series Cardan Shaft.

Please consult use for selecting

other product series.

- Universal Joint Shaft are

selected according to the load

features, calculated torques,

bearing life and operating

speed.

- Tha calculated torque is

acquired from Formulas (1), (2)

or (1), (3).

|

|

|

Table 10

:

Service Factors K |

|

Service

Factor Type |

Driven

Equipment |

K |

| Light Shock

Load |

Generators

Centrifugal

Purpose

Ventilators

Wood Handling

Machines

Belt Conveyors

Paper Machines |

1.1 to 1.3 |

|

Medium Shock

Load |

Compressor

(Multi-Cyl.)

Pumps (Multi-

Cyl.)

Small Section

Mills

Continuous Wire

Mills

Conveyor Primary

Drives |

1.3 to 1.8 |

|

Heavy Shock Load |

Marine

Transmission

Transport Roller

Tables

Continuous Tube

Mills

Continuous

Working Roller

Tables

Medium Section

Mills

Compressors

(Single-Cyl.)

Pumps (Single-Cyl.)

Mixers

Presses

Straightening

Machines

Crane Drives

Ball Mills |

2 to 3 |

|

Extra Heavy

Shock Load |

Crane Accessory

Drives

Crushers

Reversing

Working Roller

Tables

Reeling Drives

Scale Breakers

Blooming Stands |

3 to 5 |

|

Extreme Shock

Load |

Feed Roller

Drives

Plate Shears |

6 to 15 |

|

- Generally, universal joint

shafts are selected according to

the torque to be transmitted an

required bearing life. They can

also be selected checking their

torque strengths or bearing life

relation to the requirements of

the applied equipment.

- Checking the torsional

strength using Formula

Tc < Tn or Tc < Tf or Tc < Tp

...................... (4)

Where,

TC=Calculate torque, Nm

Tn=Nominal torque, NM (i.e. a

theoretic calculated value under

these pre-determined conditions;

speed of shaft n=30 rpm,

deflected angle B = 3o

, and a bearing life.

Ln=5000 hours under even load,

Tf=Permissible torque according

to the fat strength under

alternating loads, Nm

Tp=Permissible torque according

to the fat strength under

pulsating loads, Nm

Tp=1.45 Tt

|

|

|

|